Programmable logic controller, referred to as PLC, it uses a kind of programmable memory, used for its internal storage procedures, the execution of logical operations, sequence control, timing, counting and arithmetic operations and other user-oriented instructions, and through digital or analog input/output control of various types of machinery or production process. PLC has microprocessor digital electronic equipment, used to automatically control digital logic controller, control commands can be stored in memory, ready to load and run. The PROGRAMMABLE controller consists of internal CPU, instruction and data memory, input and output unit, power supply module, digital module and other modules. The ESSENCE of PLC is a special computer for industrial control, its hardware structure is basically the same as a microcomputer, the basic composition is :CPU, I/O board, display panel, memory, power supply.

High regional concentration of the industry, the market is concentrated in North America and Europe

However, we predict that the share of North America and Europe will decline to 34.16% and 40.31% respectively by 2026. Japan\'s market share will also decline, falling to 14.22%in 2026, down 0.26 percentage points from 2020. China is expected to be the fastest growing market, with its share forecast to rise to 5.47%by 2026.

Get complete sample,please click: https://www.globalmarketmonitor.com/reports/879419-plc-market-report.html

Industry 4.0 Has Developed Rapidly, Driving the Surge of Market Demand for PLC

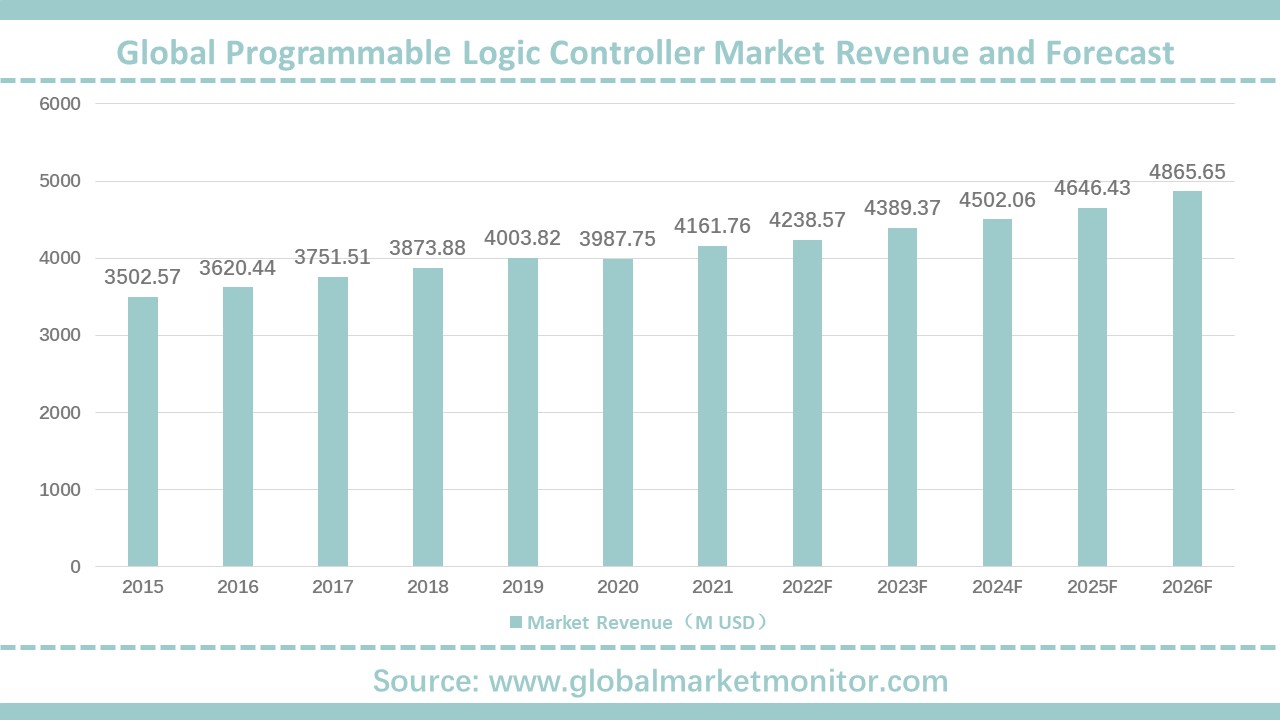

The total market revenue of the global PLC industry in 2015 was $3,502.57 million, and then began to rise year by year, increasing to $3987.75 million in 2020. Market revenue grew at a compound annual growth rate (CAGR) of 2.63% from 2015 to 2020.

It is estimated that due to the increased industrial investment in mining, oil and gas in the United States, which has a large share in North America, this promotes the use of PLCS and thus contributes to the growth of the market. SCADA is widely used in the UPSTREAM, midstream and downstream sectors of the U.S. oil and gas industry. In the upstream sector, its role is usually strictly defined as primarily supporting remote data transfer. However, due to the wide use and diversification of SCADA, the demand for PLCS will effectively increase.

However, for a long time, control system design only focuses on the realization of functions, lack of corresponding information security protection design, active control system exposed a large number of information security risks. Once these hidden dangers are used, they will directly cause serious damage to the device, such as shutdown, failure mode, automatic restart, program crash, and data area damage. "Bugs" in products cannot be fixed in a timely manner and rely on manufacturers to upgrade or issue patches. Siemens PLC\'s multiple DoS high-risk vulnerabilities are still awaiting remedies from manufacturers. For example, "Iraq nuclear accident" Siemens S7-400 PLC control system was "Stuxnet" virus attack vulnerability shocked the world, the product exists "back door" and other risks. The current international mainstream PLC control system is easily affected by the global synchronous epidemic and rapid update of a variety of mutated viruses. These factors will hamper market development to some extent.

Get complete sample,please click: https://www.globalmarketmonitor.com/reports/879419-plc-market-report.html

We provide more professional and intelligent market reports to complement your business decisions.