Polyimide

Varnish is a polyamic acid solvent resulting from the condensation

polymerization reaction of aromatic diamine and anhydride. Polyimide membranes

with excellent characteristics are produced by applying a polyimide varnish to

the base materials and then drying or heating it at high temperature.

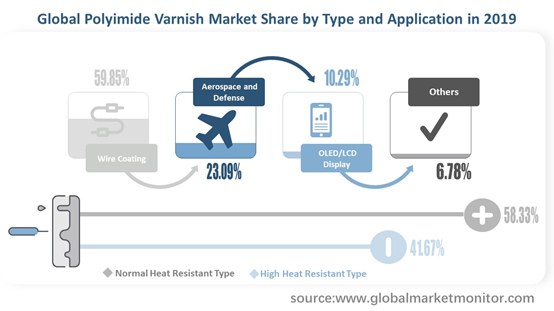

Polyimide

varnishes can be roughly divided into two types according to the degree of heat

resistance: normal heat resistance type and high heat-resistance type. Normal

heat resistant types often refer to products heat treatment highest temp around

350°C. They are polyimide varnish materials required for daily life and

production, such as those applied in display area. With heat treatment highest

temp around 450°C, the high heat-resistant type is polyimide varnish material

required by daily special industries, such as those used in aerospace and

aviation. Due to the low price, wide use and wide market of normal

heat-resistant products, the market share in 2019 was 58.33%, while the market

share of high-heat-resistant products in 2019 was only 41.67%.

Polyimide varnish is one of the best organic polymer materials with the best comprehensive properties. It is an important material in the microelectronics industry and its products are widely used. It is used as a wire coating, where the coating is heated and cured to form a film protective layer for wires, which is the most common and most widely used polyimide varnish, with a market share of 59.85% in 2019. Polyimide plastics are non-melting high temperature polymers, which strength, dimensional stability, and creep resistance remain high even at temperatures above 260°C. In addition, its high purity and low outgassing are needed for applications in the vacuum, aerospace and semiconductor industries. Polyimide varnish can also be used as a flexible substrate for OLED/LCD displays that need to endure the high-temperature post-processing. The carrier is first coated with polyimide varnish and cured, then the polyimide substrate is laser-lifted off or mechanically released after device processing.

Prospect Analysis of Polyimide Varnish Industry in Various Regions

After a period of development, polyimide varnish industry has entered a mature stage, with high industry concentration. Although there are many companies in this industry, there are very high core barriers in this industry. Leading companies with equipment, technology, capital and talent advantages are concentrated in the Asia-Pacific region, and basically monopolize the polyimide varnish market. The top three companies, UBE, IST and ELANTAS, accounted for 77.79% of the market share in 2019, with 48.70%, 17.14%and 11.95%, respectively.

Get the Complete Sample, Please Click: https://www.globalmarketmonitor.com/reports/763020-polyimide-varnish-market-report.html

The Asia-Pacific region was the largest market by revenue, which market share in 2015 is 43.97% and increased to 44.91% in 2020 with an increase of 0.94% year on year. Europe and North America ranked second and third with market shares of 24.70% and 22.68% in 2019.

Due to the complex preparation process of polyimide varnishes, American, Japanese and Korean companies monopolize the core technology and the global polyimide market. At present, the production level of polyimide varnish market in many developing regions is relatively backward, so the high-end polyimide varnishes are highly dependent on imports. The outbreaks in Japan and South Korea are expected to accelerate import substitution and improve industry profitability. At the moment, as the epidemic is still spreading in Japan and South Korea, suppliers of raw materials have been greatly affected and supply may be insufficient, which will certainly affect the countries that rely on imports from Japan and South Korea. In this environment, local production substitution is bound to accelerate and gross margins are expected to improve. With capacity tight in Japan and South Korea, profitability of local industries is expected to increase.

COVID-19 is having an impact on the global polyimide varnish industry. South Korea manufacturing sector has suffered from both supply and demand negative impacts, with many factories closed and manufacturers sharply reducing production due to disruptions in the industrial chain and the COVID-19 lockdown. The impact of COVID-19 on the European economy will continue, making it more unstable and vulnerable. It is expected that in the later stage, the impact of the epidemic on the Asian economy will continue to be felt, especially in the developing countries in Asia, whose economic foundation is relatively weak, and the internal and external impact of the epidemic will be relatively large. China recovery is key to Asia manufacturing recovery.

Global Polyimide Varnish Market Forecast Under the Impact of the Epidemic

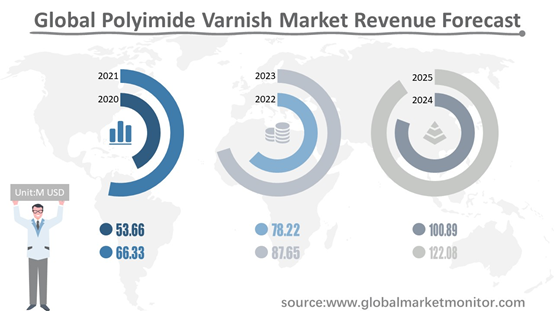

The global polyimide varnishes market grew from $30.89 million in 2015 to $52.63 million in 2019, with a growing rate of more than 10%. During the epidemic period, the resumption of work and production of a large number of enterprises in the industry was affected by the epidemic prevention and control, and the movement and activities of people were restricted, which in turn affected the logistics. Besides, production of the industry was affected by the insufficient supply of raw materials and labor force, so the growth was slowed down. However, after the outbreak of the epidemic, a new round of information technology innovation and industrial transformation in electronic information, new energy, new infrastructure, aerospace and other development fields brought unprecedented development opportunities, so the upstream material polyimide varnish market demand increased.

As the

penetration rate of flexible OLED phones continues to rise, the market for

polyimide varnishes will further expand. In addition, 5G mobile phone terminals

will grow rapidly in the future, contributing to the rapid development of the

smartphone market, which will also boost the demand for polyimide varnishes. In

many developing regions, governments strongly support the development of

high-performance materials and provide strong policy support. As a result, we

forecast that the market revenue will reach $122.08 million by 2025.

In the

future, lessons will be learned for the epidemy-hit polyimide varnish industry.

Many surviving enterprises will actively transform, using digital

transformation and remote intelligent services, to help improve the efficiency

of employee collaboration, grasp the key elements to promote business growth,

more effectively respond to market demand fluctuations, and achieve product

innovation, which is also the inevitable path for future enterprise

development.

We provide more professional and intelligent market reports to complement your business decisions.