Chemical mechanical planarization (CMP), also called Chemical-Mechanical Polishing, is a technology in the manufacturing process of semiconductor devices that uses chemical corrosion and mechanical force to planarize the wafer or substrate and can be applied in advanced integrated circuit manufacturing. In the 1970s, multi-layer metallization technology was introduced into the integrated circuit manufacturing process. This technology made effective use of the vertical space of the chip and improved the integration of devices. However, this technology has aggravated the unevenness of the surface of the silicon wafer, and the resulting series of problems have seriously affected the development of large-scale integrated circuits. In response to this problem, the industry has developed a variety of planarization technologies, including reverse engraving, glass reflow, and spin coating, but the effect is not satisfactory. At the end of the 1980s, IBM developed the CMP technology to apply it to the planarization of silicon wafers. Its surface planarization effect was greatly improved compared with the traditional planarization technology, which made it a large-scale technology. Flattening technology has a key position in integrated circuit manufacturing. Defects and residues either deposited or formed during the planarization process that can adversely affect product yield are subsequently removed in the post-CMP cleaning step. Aqueous formulations employed for post-CMP (PCMP) cleaning is designed to protect the planarized metals and dielectrics preventing metal corrosion while providing a smooth defect-free wafer surface.

According to different contents of solution, it can be divided into acidic material and alkaline material. Acidic material refers to particle removal by the acidic agent in the post CMP cleaning process. This single chemistry solution is designed to clean ceria slurry particles, as well as minimizing residual cerium ions post-CMP. Alkaline material can be used with acidic or basic barrier slurries; and can be used with advanced barrier films with excellent corrosion resistance, offering flexibility in dilution to meet low cost-of-ownership targets for all equipment cleaning modules. In 2019, the market share of these two types of solution was 56.73% and 43.27%, respectively. It can be seen that the market demand for acidic material is higher.

Metal Impurities are chemical substances inside a confined amount of metal, which differ from the chemical composition of the material or compound. Organic residues are carbon-based substances of biological origin that may survive in a broad range of archaeological contexts, including the fabric of pottery vessels, food preparation and floor surfaces, midden or latrine deposits, and archaeological sediments themselves. In 2019, the market share of metal impurity and organic residue cleaning was 64.82% and 35.18%, respectively. The solution is more widely used in the metal impurity industry.

The Current Situation of Global Post CMP Solutions Industry Market

China was the largest revenue market with a market share of 32.33% in 2015 and 33.96% in 2019, an increase of 1.63%. In 2019, the North America market share was 19.04%, ranking second. Post CMP Cleaning Solutions companies are mainly from USA; the industry concentrate rate is high. The top three companies are Entegris, Versum Materials (Merck KGaA), Mitsubishi Chemical Corporation with the revenue market share of 25.12%, 21.32% and 15.42% in 2019.

Post CMP Cleaning Solutions is widely used in electronics manufacturing plants in North America, Japan and other regions with a large market. Downstream demand is the most important driving factor in the Post CMP Cleaning Solutions industry. With the improvement of the quality of raw materials, the growth rate of demand for Post CMP Cleaning Solutions products from electronics factories has slowed down, resulting in a slowdown in the growth rate of the Post CMP Cleaning Solutions industry. This requires companies to look for new markets and continuously improve product quality in order to seek new growth opportunities.

Get the complete sample, please click: https://www.globalmarketmonitor.com/reports/762848-post-cmp-cleaning-solutions-market-report.html

The COVID-19 epidemic has postponed or canceled the technology exhibition, shut down operations in the electronics, industrial and automotive fields, and also harmed the supply chain of CMP slurry raw materials. These factors will damage the prospects of the CMP slurry market in the short term. And most of the factories have not yet been fully operational, which also limits the overall supply of the CMP Slurry market, thereby educing the ability to deal with the backlog and quickly recover from losses. The stagnation caused by COVID-19 in the upstream industry will hinder the short-term development of Post CMP Cleaning Solutions.

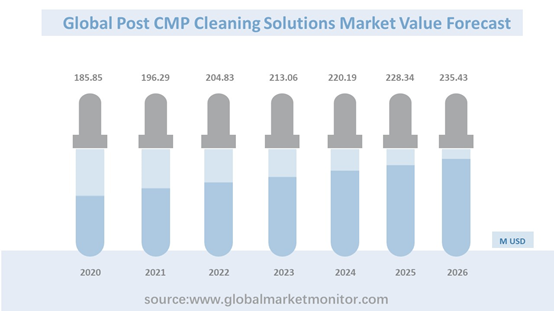

Global Post CMP Cleaning Solutions Industry Market Forecast

According to our research, the Global Post CMP Cleaning Solutions market has a total revenue of 156.19 M USD back in 2015, and increased to 188.64 M USD in 2019. We made a series of functional calculation and deduced the data of past 5 years with scientific model. Finally, we made the prediction that the value of Post CMP Cleaning Solutions markets can be 235.43 M USD by 2026. The CAGR of Post CMP Cleaning Solutions is 4.02% from 2018 to 2024.

In the field of cleaning technology, product development is a more important development strategy. Because only the product has an advantage, a company can gain a foothold in the Post CMP Cleaning Solutions industry. Therefore, a large number of Post CMP Cleaning Solutions companies choose to continuously launch new products or services in the existing market. Product development can be used to extend the proposed offer to current customers to increase the turnover of businesses. Post CMP Cleaning Solutions companies can specifically choose to invest in the research and development of other products; obtain patents to produce others products; purchase products and (brand) them to achieve corporate growth.

There are two main types of common toxicity of metal impurities: neurotoxicity and nephrotoxicity. For example: long-term exposure to lead can cause mental retardation in children. Mercury can cause deafness and mental disorders. Mizugure disease of Japan is caused by methylmercury, and this effect may continue in future generations. Lead, cadmium, and mercury are all nephrotoxic. In the case of long-term exposure, the combined use of arsenic and cadmium may even cause superimposition of nephrotoxicity. Therefore, the cleaning of metal impurities is of high importance, driving the growth of this industry.

With the continuous improvement of the economic development speed, the awareness of global environmental protection is also increasing. Strict environmental policies have put forward higher requirements for the Post CMP Cleaning Solutions industry. First of all, tetramethylammonium hydroxide is banned in more and more regions, which will put forward higher requirements for product development and innovation. Secondly, environmental protection policies and customer EHS requirements differ between different regions and different countries, which poses challenges to large multinational companies in the industry. All these factors may hinder the development of this industry.

We provide more professional and intelligent market reports to complement your business decisions.