Acrylic

rubber, known by the chemical name alkyl acrylate copolymer (ACM), is a type of

specialty rubber that has outstanding resistance to hot oil and oxidation. Because

they have no unsaturated bonds, they have good ozone resistance and low gas

permeability. Their disadvantages of poor moisture resistance, acid resistance

and alkali resistance limit the use of acrylic rubber in some applications,

thus hinder the demand for this product.

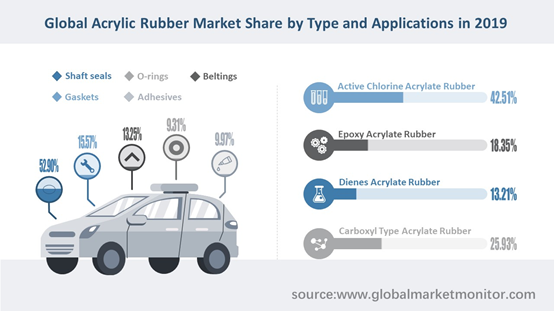

The

acrylic rubber may be a copolymer of an acrylic acid alkyl ester and a cure

site monomer. The cure site monomer may have at least one functional group

selected from an epoxy group, a carboxyl group, a dienyl group and an active

chlorine group, which may be copolymerized with an acrylic acid alkyl ester as

needed to advance intermolecular crosslinking, and the hardness or elongation

characteristics of a resulting acrylic rubber can be controlled. Therefore, acrylic

rubber can be divided into active chlorine acrylate rubber, epoxy acrylate

rubber, dienes acrylate rubber and carboxyl acrylate rubber according to

different types.

Acrylic rubber is widely used in under-hood automotive applications and is commonly used to make beltings, gaskets, shaft seals, O-rings, and adhesives. A Belting is a loop of flexible material used to link two or more rotating shafts mechanically, most often parallel. A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. Shaft seal, also called Oil Seal, in machinery, a device that prevents the passage of fluids along a rotating shaft. An O-ring is a mechanical gasket in the shape of a torus. It is designed to be seated in a groove and compressed during assembly between two or more parts, creating a seal at the interface. Adhesive is capable of holding materials together in a functional manner by surface attachment that resists separation.

Prospect Analysis of Acrylic Rubber Industry in Various Regions

The Asia-Pacific region is the largest revenue market. In 2015, its market value reached US$27.79 million, with a market share of 44.46%. By 2019, its market share has increased to 45.59%, a year-on-year increase of 1.13%. North America and Europe closely follow the development of the Asia-Pacific region, ranking second and third with a market value of US$1.9428 million and US$1.7322 million in 2019. Although the Middle East and Africa have a market share of only 3.61% in 2019, the economies of emerging countries such as Egypt and Nigeria are developing rapidly. In the future, the acrylic rubber market will become one of the fastest growing regions in the world with a large demand.

Get the Complete Sample, Please Click: https://www.globalmarketmonitor.com/reports/762792-acrylic-rubber-market-report.html

Acrylic rubber companies are mainly concentrated in the Asia-Pacific region and North America. In 2019, the top three companies, Zeon, Denka and NOK, accounted for up to 78.09 %market share, respectively 37.06%, 22.66% and 18.38%.

Driven by the increase in the production of internal combustion engine and turbocharged engine vehicles, the demand for acrylic rubber in Asia is expected to grow steadily. The Covid-19 is having a serious impact on the European acrylic rubber industry, mainly reflected in downstream demand, which is expected to continue, increasing the instability and vulnerability of European economic development. In addition, several automakers in North America will idle their production in response to the Covid-19 virus. The interruption of the production and supply chain will further worsen. Automobile production and automobile sales will be affected, so the demand for acrylic rubber-related products will also be affected.

Acrylic Rubber Market Will Further Expand

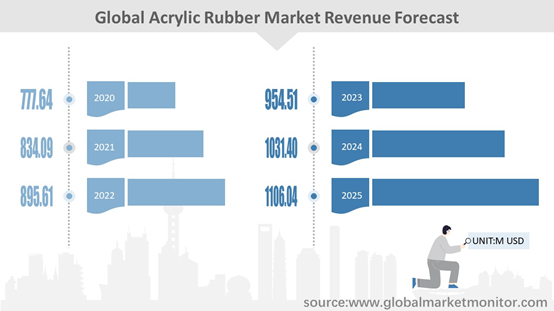

Although the growth of the automotive industry has slowed in recent years, the demand for acrylic rubber from the automotive industry remains significant, which is an important factor driving the global acrylic rubber market. The rapid urbanization and industrialization of emerging economies, increasing demand for high-efficient energy, combined with advanced technologies that have developed fuel-efficient nacelles or components and increased combustion temperatures, have had a positive impact on the global acrylic rubber market. The global acrylic acid industry market value was $613.62 million in 2015 and increased to $777.64 million in 2020.

In the

long term, as the epidemic gradually improves or ends, the impact on the

acrylic rubber industry will gradually diminish, and the production and sales

volume will recover to the original level and gradually increase. In addition,

the pandemic will promote automated production in the industry, enabling

manufacturers to hire more complex workers, rely less on labor and better cope

with labor fluctuations. Growth in end-use industries such as consumer goods

and plastics is also expected to spur growth in the acrylic rubber market. The

global acrylic rubber market is driven by increasing consumer and manufacturer awareness

of durable, efficient and cost-effective products. Therefore, we forecast that

the acrylic acid market will continue to grow at a growth rate of more than 7%

in the future, reaching a market value of $110,604 million by 2025.

Generally

speaking, the labor cost price will be in the state of rising and the industry

cost will increase, bringing challenges to the enterprises in the industry.

From the supply side during the epidemic period, the company operating pressure

will increase due to the delayed arrival of workers and logistics

transportation problems. In addition, the low availability of raw materials is

one of the major factors that may hinder the growth of the market during the

forecast period.

We provide more professional and intelligent market reports to complement your business decisions.