A material that responds with very high resistance to the flow of electrical current or totally resists electric current is called an insulating material. In insulating materials, the valence electrons are tightly bonded to their atoms. Insulation on an electric motor prevents the interconnection of windings and the winding to earth. Insulating materials are characterized not only by excellent electrical characteristics but also by good levels of thermal conductivity, tearing resistance, flexural strength, mechanical recovery, foldability, punching property, flexibility, as well as readiness to absorb impregnating agents. Therefore, it can ensure the automation of manufacturing processes when windings are being inserted or pulled in.

Insulating material is a key material to ensure the reliable, long-lasting and safe operation of electrical equipment, especially electric power equipment. Different electrical equipment has different requirements for the performance of insulating materials. Insulating materials used in high-voltage electrical equipment such as high-voltage motors and high-voltage cables require high breakdown strength and low dielectric loss. The main requirements of low-voltage electrical appliances are mechanical strength, elongation at break and heat resistance.

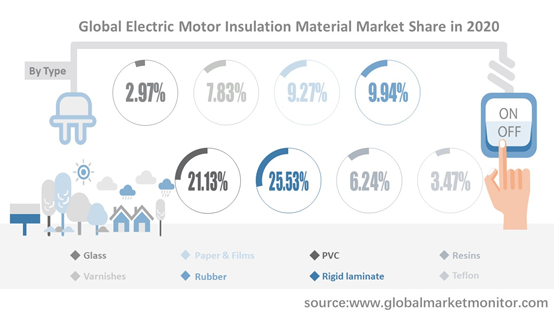

Glass, varnish, paper and film, rubber, PVC, rigid laminate, resin and Teflon can all be used as insulating materials for electric motors. Among them, rigid laminates have excellent chemical resistance, corrosion resistance, high temperature resistance and electrical tracking resistance, so its market is the largest, accounting for 25.53% of the market share in 2020. In addition, the formula of polyvinyl chloride (PVC) can be adjusted according to different applications and different characteristics of the motor, which is very convenient to use. Therefore, its market is also relatively broad, with a market share of 21.13% in 2020. Although Teflon is very durable and can withstand very high and low temperatures, it is usually only used in extreme environments with a high cost, so it only accounts for 3.47% of the market share.

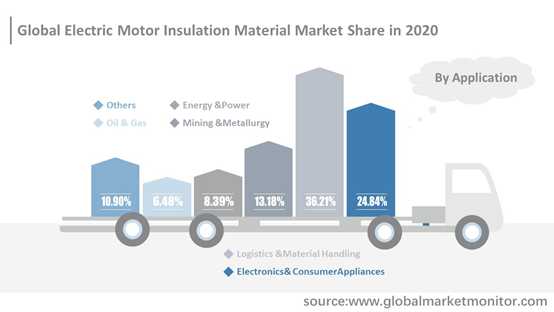

As a basic material, electric motor insulation materials are widely used in the fields of electronics and consumer appliances, such as air conditioners, washing machines, refrigerators and other household appliances. Logistics and material handling are the most widely used fields of motor insulation materials, accounting for 36.21% of the market share in 2020. These motors use automated motor equipment and automotive products, such as the application of brushless DC motor systems in logistics intelligent sorting systems. In addition, motor insulation materials can also be applied to mine power system motors, as well as special frequency conversion motors for petroleum platforms in the petroleum, special motors for high-power bipolar compressors, and motors with low starting current in the oil and gas industries.

Prospect Analysis of the Electric Motor Insulation Material Industry in Various Regions

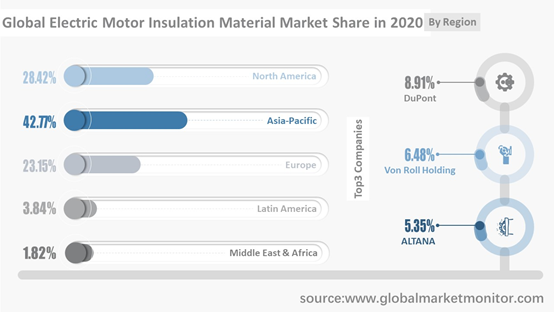

Asia-Pacific was the largest revenue market with a market share of 37.53% in 2015 and 37.89% in 2020 with an increase of 0.36%. North America ranked the second market with the market share of 34.86% in 2019. Also, development of economy, increase downstream demand, technology innovation progress in emerging economies such as China and India have led to an increase in demand, so the Asia Pacific market for electric motor insulation material are expected to be the market with the most promising growth rate.

Get the Complete Sample, Please Click: https://www.globalmarketmonitor.com/reports/762525-electric-motor-insulation-material-market-report.html

Electric Motor Insulation Material industry concentrate rate is relatively low. The top three companies are DuPont, Von Roll Holding and ALTANA with the revenue market share of 8.91%, 6.48% and 5.35% in 2019.

After the economic slowdown caused by trade tensions and COVID-19, most governments in the affected regions have adopted infrastructure as part of their strategy to stimulate economic growth. The downstream industry will gradually recover, driving the demand for electric motor insulation materials. After the epidemic is relieved in various places, electric motor insulation materials will face development opportunities.

Agricultural mechanization is the process of using equipment, machinery and tools to promote agriculture and food production. It includes all agricultural machinery powered by electricity, which is very suitable for low-load tasks, such as electric rice mills, hydraulic machines, grinders and submersible pumps. With the development of agricultural mechanization, some countries and regions have huge market potential, especially those countries and regions whose economies are highly dependent on agriculture such as Vietnam, Argentina, India, and Sri Lanka, with a low degree of mechanization, relying on manpower for agricultural activities. Therefore, their demand for low-cost and energy-saving electric motors will increase, which also means that the demand for electric motor insulation materials may also increase.

The Electric Motor Insulation Material Market Will Tend to Develop Moderately

With personal continuous pursuit of a convenient living environment, pursuit of economic benefits of large-scale production for enterprises, and demand for automation, intelligence, and modernization of industrial and agricultural production equipment, the rapid development and progress of motor technology has been promoted. The scope of application of special motors has expanded to a wider range of fields, and has increasingly become a key technology in many fields. The application of new materials has created favorable conditions for improving the performance of motor products and reducing costs. Microelectronics technology, modern control technology, computer technology and power electronics technology have promoted the continuous progress of special motors to high performance. Based on the above analysis, the increase in electric motor market demand will gradually drive the market demand for electric motor insulation materials.

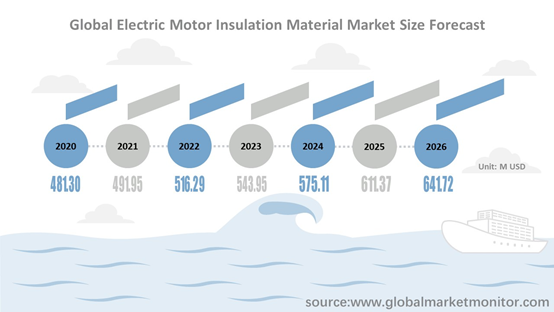

According to the research, the global electric motor insulation material market has a total value of 384.58 M USD back in 2015, and increased to 481.30 M USD in 2020. We made the prediction that the value of electric motor insulation material markets can be 641.72 M USD by 2026. The CAGR of electric motor insulation material is 4.91% from 2020 to 2026.

The advancement and stability of insulating materials are of great significance for ensuring the reliability and stability of power generation, power transmission and transformation, and electrical equipment operation. In addition, with the development of motor insulation material technology and application, encouraging the production of environmentally friendly and resource-saving materials is the focus and direction of industrial restructuring. Therefore, enterprises must keep pace with the times, innovate continuously, and achieve sustainable development.

Get the Complete Sample, Please Click: https://www.globalmarketmonitor.com/reports/762525-electric-motor-insulation-material-market-report.htmlWe provide more professional and intelligent market reports to complement your business decisions.