Global Electro-Galvanizing Market Overview

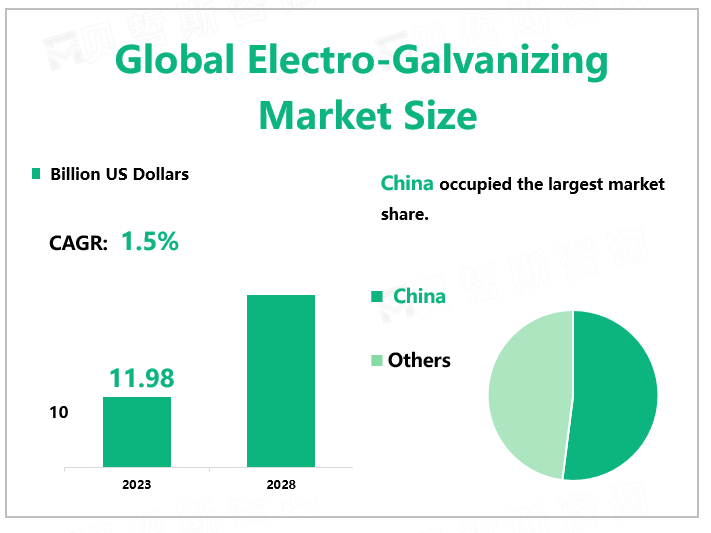

According to Global Market Monitor, the global electro-galvanizing market size was $11.98 billion in 2023 with a CAGR of 1.5% from 2023 to 2028.

Electro-galvanizing is a process of bonding a layer of zinc to steel to prevent corrosion, involving electroplating that runs current through a brine/zinc solution with a zinc anode and a steel conductor.Electroplated products have a short life due to the thin zinc layer. In the short term, if the pickling is insufficient and the air is humid, dezincification and oxidation will occur in a few weeks.

China Occupied the Largest Market Share.

The electro-galvanizing market in the Asia Pacific is estimated to witness a prominent pace of growth, with an increase in the application of galvanized steel in the automotive component manufacturing segment in established automotive manufacturing clusters in China and Japan. Commendable steel manufacturing in the region is prompting massive market development. Additionally, the growing demand for pump control panels in agricultural applications such as irrigation, chemical injection, dairy farms, and horticulture is anticipated to drive the market in the forecast period.

Market Drivers and Challenges

The electro-galvanizing is a completely different process from hot dip galvanizing, in which a zinc coating is applied to the steel, wherein the anode is zinc, the cathode is steel, and the electrolyte is zinc sulfate. This process consumes a lot of electricity and increases the cost of electroplating, so the price of electro-galvanizing is relatively high.Electro galvanizing has superior capabilities to hot-dipped products when it comes to slight bending and deep drawing operations. The impressive capabilities to provide supreme performance in unexposed environments are bolstering its demand across diverse applications. Additionally, electro-galvanized metal products are more durable and have a vibrant and shinier surface compared to their hot-dipped counterparts. These steel poses uniform thickness that helps products to have more robust joining and forming operations. Due to the rust-resistant zinc coating, the electro-galvanized steel also exhibits remarkable anti-resistant properties making its application suitable even in damp and moist atmospheres.

|

Drivers |

The use of fingerprint-resistant electro-galvanized steel sheets is increasing. |

|

High-end cars have been using electro-galvanized steel. |

|

|

Increasing per capita disposable income |

|

|

Electro galvanizing can replace expensive electroplating products. |

|

|

Hot-dip galvanizing market oversupply |

|

|

Challenges |

Electro galvanizing has a short service life. |

|

High cost of electro-galvanizing |

|

|

The electroplating zinc product process is difficult to advance. |

We provide more professional and intelligent market reports to complement your business decisions.