Global Needle Coke Market Overview

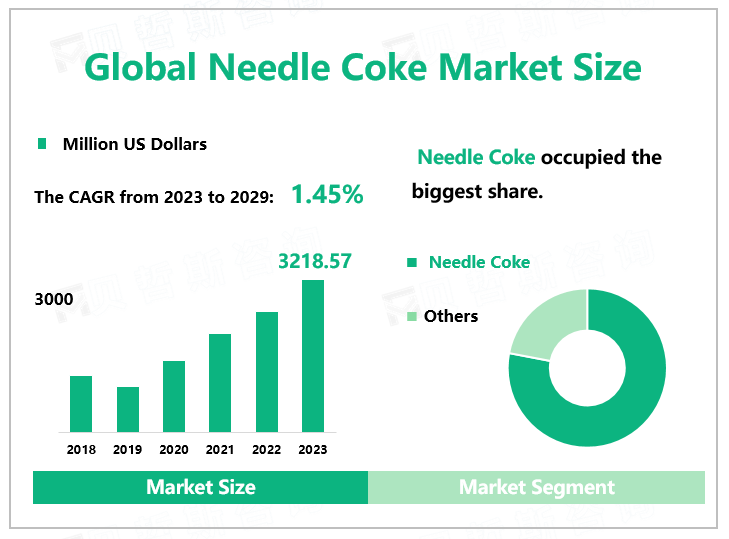

According to Global Market Monitor, the global needle coke market size was $3218.57 million in 2023 with a CAGR of 1.45% from 2023 to 2029.

Needle coke is a special grade of petroleum coke, which is valued because of its crystal structure, which makes it a good material for making electrodes. Needle coke is usually produced by a dedicated cooker that uses low-sulfur FCC slurry as a raw material. The high aromatic content of the FCC slurry results in the desired needle coke characteristics. With the progress in science and technology, investment of companies, there will be more opportunities in needle coke, companies may pay attention to their production technology, keep on innovation and offer more cost effective, high performance and environment friendly products in the future.

Market Trends

Electric furnace steelmaking has become an important development direction of steelmaking enterprises in recent years due to its advantages of low energy consumption and low pollution emissions. Electric furnace steelmaking uses scrap steel as the main raw material, three-phase alternating current as the power source, and uses the high temperature of the electric current to generate an arc between the graphite electrode and the metal material to heat, melt, and refine the metal. High-power and ultra-high-power graphite electrodes are necessary consumables for electric furnace steelmaking. Graphite electrodes prepared from needle coke have the advantages of high electrical conductivity, small thermal expansion coefficient, and high mechanical strength, which can meet the quality of large-capacity electric arc furnaces. Require. High-power and ultra-high-power graphite electrodes have also become the main application direction of needle coke.

Raw materials such as coal tar pitch often require raw material pretreatment, and the pretreatment process is very complicated and costly, which is not conducive to industrial production. Therefore, looking for raw materials that do not require or only need simple pretreatment will greatly help the next step in the expansion of needle coke production. At the same time, exploring low-cost, simple process raw material pretreatment methods is also an effective solution to this problem.Existing physical disturbance process research is still relatively macro, with few exploration factors, and it is difficult to carry out quantitative control and expand production. Increasing physical disturbance will inevitably require designing and updating equipment, as well as increasing operating costs. Therefore, the quantitative analysis of physical disturbances and the expansion and energy-saving design of reaction equipment should also be the next research direction.The high temperature in the calcination process, excessive energy consumption, and high requirements for equipment and materials directly lead to an increase in preparation costs. Finding new inhibitors or catalysts, reducing energy consumption and calcination equipment requirements are important directions that researchers need to explore.

|

By Type |

Coal-based Needle Coke |

|

Petroleum-based Needle Coke |

|

|

Coal-based needle coke segment accounts for the largest share. |

|

|

By Application |

Special Carbon Material |

|

Graphite Electrode |

|

|

Others |

|

|

The largest segment by application is the graphite electrode. |

We provide more professional and intelligent market reports to complement your business decisions.